This is how usually small and growing businesses work with their sales forecasting and inventory determination, right? And while this is the legacy approach, a lot of businesses have been carrying on with the practice to date.

Supply Chain latency and gaps

Why legacy organizations need to make the move?

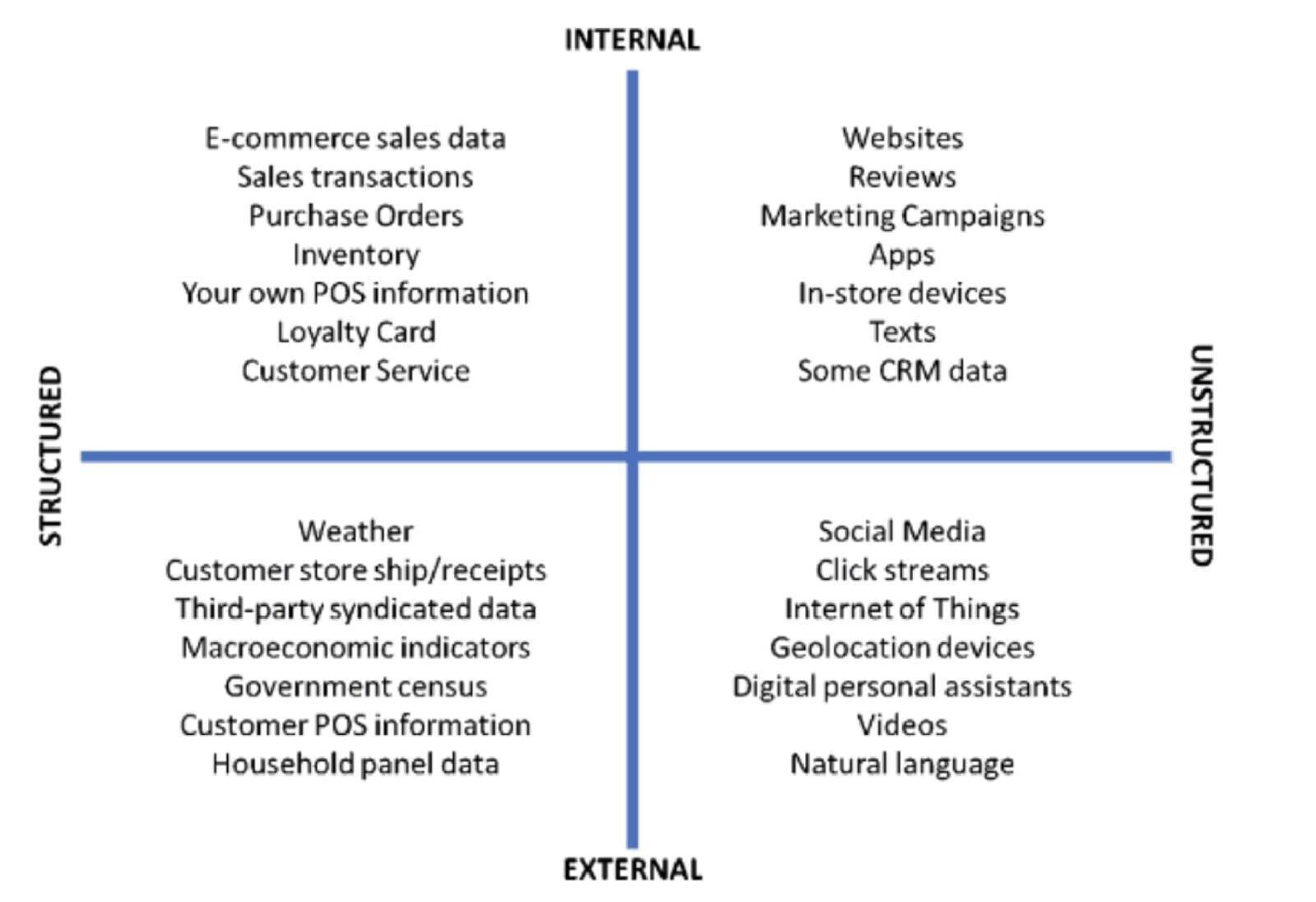

If your organization finds itself in the space, there is need for it to anticipate customer demand across several channels and drive real-time decision making. This not only maximizes business outcome but also brings down the gap between when a product is ordered and the time in delivering it. The dynamic environment in which supply chain organizations operate today has made it necessary to detect supply and demand in real time, reduce cycle time, and provide accurate sales forecasts.

Forecasting sales in a ‘Smart Operations’ environment

The accuracy of your sales forecast plays a crucial role in the success of your organization because these forecasts allow leaders make smart decisions for goal setting. It also detects issues in order to avoid or mitigate them early rather than at the end of the month or quarter.

For instance, if data shows that your sales team is trending 40% below quota, you can quickly figure out the problem and act. Accurate Sales forecasts enable manufacturing operations and businesses to forecast demand months in advance to ensure order fulfillment and adequate inventory available for supply. Forecasts are very important and crucial to your organization’s success but there are factors that can limit your forecasts and provide wild inaccurate results.

The 'Smart Operations' course of action

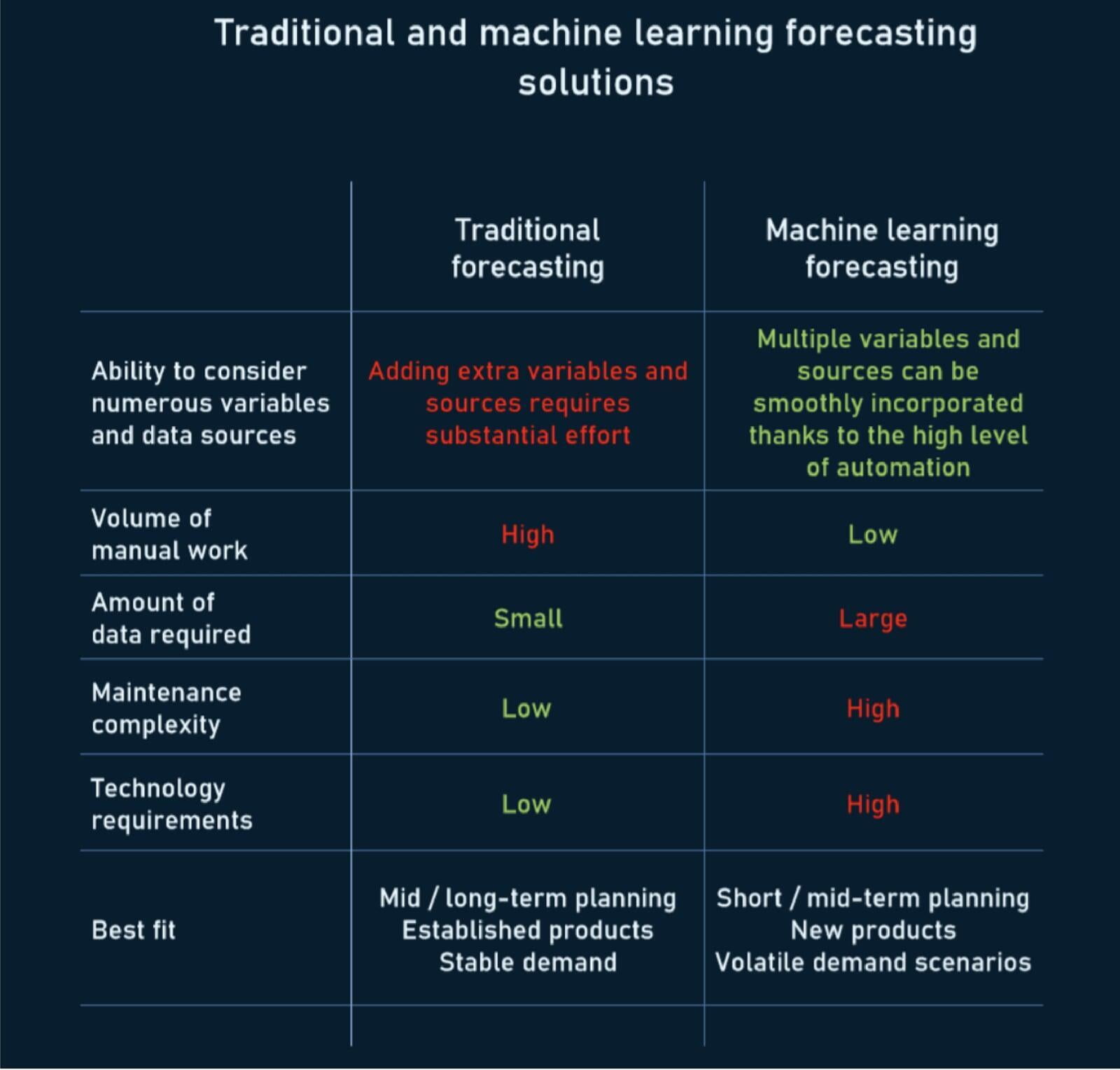

Supply chains need to respond to changes in information and insight to drive better decision making and this requires a tight alignment between planning, collaboration and decision making. Organizations today are adopting the connected function of Smart Operations as part of their digital manufacturing pursuit to gain an edge over their competitors. Smart Operations synchronize all aspects of manufacturing and operations with the use of Connectivity, Intelligence, and Automation. This is how Smart Operations can help your organization improve sales forecasts:

Supply chains rely on information and insights and the integration of Smart operations can help these organizations detect changes in the market and also eliminate delivery lead time, data latency and quality issues. Emerging supply chain organizations will be able to sense demand across multiple channels and the use of advanced analytics will provide better flexibility, delivery, visibility, and efficient tools for real-time decision-making.